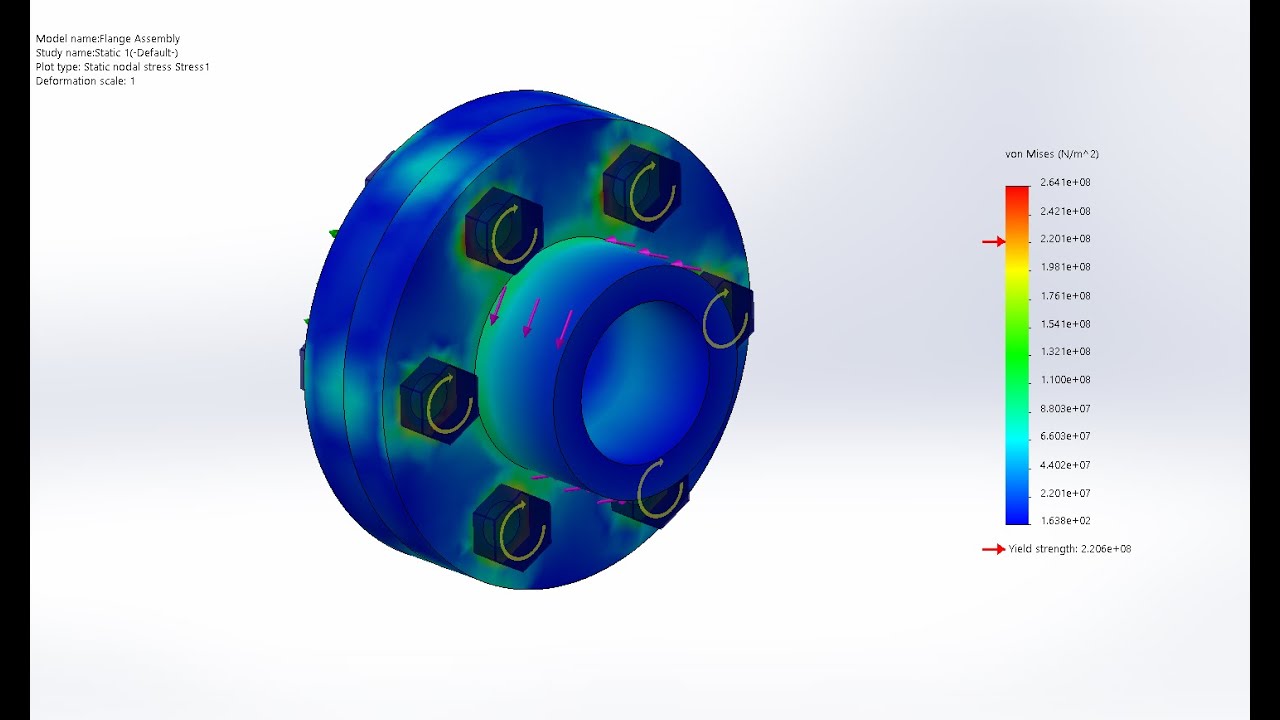

Bolted Connections: A Simplified Approach to Structural Analysis with Bolt Connectors

Bolted connections are the workhorses of the engineering world, holding structures together from bridges and buildings to airplanes and automobiles. But simulating these seemingly simple components in finite element analysis (FEA) can be a challenge. The intricate details of bolts can significantly increase the complexity of the mesh and slow down computation times.

Here, we’ll explore the world of bolted connections in FEA and introduce a method to simplify their simulation. We’ll also delve into some interesting facts about these crucial components.

The Romans were the first to use iron bolts extensively in construction, particularly for aqueducts and temples. These early bolts were often L-shaped or T-shaped, and they were secured with wedges.

The Challenge of Simulating Bolted Connections

There are a few key hurdles to overcome when simulating bolted connections in FEA:

- Mesh Complexity: The intricate geometry of a bolt, with its threads and head, requires a very fine mesh to capture its behavior accurately. This fine mesh can significantly increase the time it takes to run a simulation.

- Contact Modeling: The contact between the bolt and the surrounding parts needs to be accurately modeled to capture the interaction between them. This can be a complex task, especially for non-perfectly aligned connections.

- Material Properties: The material properties of both the bolt and the surrounding parts need to be considered to achieve accurate results. This can involve factors like elasticity, yield strength, and fatigue resistance.

A Simpler Approach: Introducing Bolt Connectors

Thankfully, there’s a way to streamline the simulation of bolted connections. Enter Bolt Connectors, a method that utilizes virtual elements to represent real bolts. These virtual bolts are essentially beam elements that connect the parts they join.

Here’s why Bolt Connectors are a game-changer:

- Reduced Mesh Complexity: Virtual bolts are much simpler than real bolts, leading to a coarser mesh and significantly shorter computation times. This can be a huge advantage for complex structures with numerous bolted connections.

- Accurate Results: Don’t be fooled by their simplicity! Bolt Connectors have been validated against real-world testing data and are capable of providing accurate results for a wide variety of bolted connections.

- Easy to Use: Applying Bolt Connectors is a breeze. With just a few clicks, you can define the virtual bolt’s properties and connect it to the relevant parts in your FEA model.

Software with Built-in Bolt Connector Functionality

Several popular FEA software programs offer Bolt Connector functionality readily available for use. Here are a few examples:

- ANSYS (https://www.ansys.com/)

- Abaqus (https://www.3ds.com/products/simulia/abaqus)

- SolidWorks Simulation (Through the SOLIDWORKS Simulation Professional add-on)https://www.solidworks.com/lp/getting-started-simulation-3dexperience-platform)

Applying Bolt Connectors: A Step-by-Step Guide (General Approach)

While the specific steps may vary depending on your chosen FEA software, the general process for applying Bolt Connectors follows a similar pattern:

- Import your geometry: Upload your 3D model of the structure into your FEA software.

- Define Material Properties: Specify the material properties for both the bolt and the surrounding parts. This includes factors like elasticity, yield strength, and Poisson’s ratio.

- Activate Bolt Connectors: Look for the “Connectors” section in your FEA software and select the “Bolt Connector” option.

- Define Virtual Bolt Properties: Specify the diameter, length, and material properties of the virtual bolt to represent the real bolt.

- Connect the Parts: Choose the parts that the virtual bolt will connect, ensuring proper alignment.

- Run the Simulation: With your Bolt Connectors in place, you’re ready to run your FEA simulation and analyze the results.

A comprehensive guide by SimScale is available here: https://www.simscale.com/blog/bolt-connectors-simplifying-structural-analysis/

Benefits of Using Bolt Connectors

By incorporating Bolt Connectors into your FEA workflow, you can experience several advantages:

- Reduced Computation Time: The simpler mesh associated with Bolt Connectors significantly reduces the time it takes to run your simulation, allowing you to iterate on your design more quickly.

- Accurate Results: Despite their simplicity, Bolt Connectors deliver reliable results, ensuring confidence in your structural analysis.

- Ease of Use: The user-friendly interface of Bolt Connectors allows you to quickly define and apply them to your model, saving you valuable time and effort.

In conclusion, Bolt Connectors offer a powerful and efficient way to simulate bolted connections in FEA. By leveraging this approach, you can streamline your structural analysis process, achieve accurate results, and free up valuable time for further design exploration.